Free Cooling Systems

As a general rule of thumb, free cooling is a method of bypassing the chillers when ambient conditions are favorable to provide cooling, but how does this process work?

Many industrial processes require that chilled water be available throughout the year for heat exchange. During the colder times of the year (fall through spring – depending on location) a system’s cooling tower may have the capacity to produce water cool enough to eliminate the need to operate a chiller. This is known as “free” cooling, “ambient” cooling, or “evaporative” chilling. Essentially, the term free cooling means that cooling tower water is provided directly to the closed system in which chilled water is normally circulated from a chiller. For sake of ease, often cooling tower water is circulated through a heat-exchanger for cooling the closed system chilled water indirectly. Nonetheless, bypassing the chiller allows cost-conscious building or process owners and operators to take advantage of naturally occurring climate conditions to save operational costs.

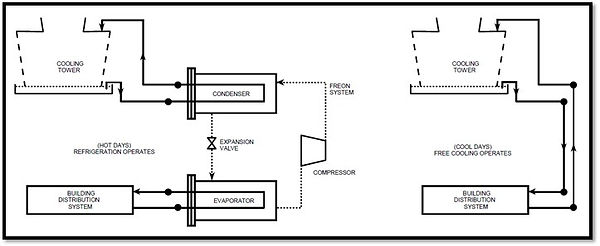

Figure 1: Cooling Tower Schematic for “free cooling” directly into chilled water loop.

Figure 1 presents an overly simplified diagram of free cooling when water is directly connected with the closed chilled water loop. Since water treatment requirements for cooling tower water are different from closed circulating systems, there may be some consequences of adding an aerated water supply to such loops. Cooling tower water can introduce additional suspended solids into these systems that are not designed for such corrosive materials. Also, as water temperatures decrease, the scale formation tendency decreases as well and may loosen or disperse any scale present in cooling towers which would contribute to the solids content moving through chilled loops. Installation of a side-stream filter may be justified for these reasons if evidence of high suspended materials is available. Special consideration should be given to pipe material, flow rates, and water chemistry. Corrosion coupons results can provide valuable information during free cooling periods and should be installed to validate the current selection of inhibitor(s). Although this method of free cooling is very efficient, the contamination issues common in cooling tower systems cause concern about fouling, which requires ongoing treatment.

Heat Exchangers

In order to isolate the chilled water loop from the cooling tower, plate-and-frame heat exchangers or water-side economizers can be used. This method is popular due to the fact that it eliminates the potential for contamination of the chilled water loop and still offers efficiency. When determining the size and capacity of heat exchangers, the lowest possible temperature difference between circuits (5°F or less) is optimal. As the differential temperature rises, the larger and pricier the heat exchanger. There are several variations of isolating the chilled water loop from the cooling tower. For instance, it is possible to circulate cooling tower water through the condenser and maintain the chilled water loop in the evaporator which would still provide the separation. There are several parameters that contribute to properly sizing a cooling tower, and the difference in load between the summer and winter months may not work with just one system. For instance, if the summer load requires a nominal capacity of 600 tons of cooling, while the winter load demands only 250 tons of cooling, providing one 600 ton cooling tower is not feasible as the water loading on the tower will be less than half during winter operation. As flow decreases in the cooling tower, the potential for scale formation and freezing of the fill and other components increases. In this scenario, having 2 – 300 ton chillers would be more suitable for cost conservation in the cold month.

Freeze Protection

It is common that cooling towers components in the free cooling scenario operate at subfreezing temperatures, and without adequate protection can be susceptible to icing and eventual system failure. Conditions such as lower flow rates and reduced plant load may lead to such failures and need to be taken into consideration.

Electric immersion heaters in cold water basins can be utilized to help keep the water in the basin above freezing. Heaters for this purpose should be chosen based on parameters such as basin capacity, temperature controls and expected operating temperatures. All piping exposed to the elements should be heat-traced to avoid freezing. If at all possible, ideally a remote sump could be installed outside of the elements to avoid freezing altogether. Proper control of the cooling tower fans is critical to avoid freeze up. A variable speed drive is recommended as it provides superior water temperature control. To avoid ice build-up, de-icing fan controls can also help maintain winter operation.

Figure 2: Dry Basin system schematic

Free cooling is a relatively simple concept that can be applied to new and existing cooling tower projects with relative ease. A free cooling configuration is not completely “free” because the tower, chilled water pumps, and tower fans still must be operated. Nonetheless, facilities can take advantage of naturally occurring climate conditions to save system operating costs due to the reduction of chiller runtime. The concept has been applied successfully for many years to the delight of many system owners, making sure that components aren’t susceptible to excessive freezing.

List of Resources:

[1] Cold Weather Operation of Cooling Towers. (2016). MARLEY - Thermal Science, 1–8.

[2] Operating Cooling Towers In Freezing Weather. (2007). Technical Report - SPX, 1–8.

[3] BAC. (2015). Minimizing Energy Costs with Free Cooling. BAC Technical Resources, V, J50–J61.

[4] TRANE. (1999). Centrifugal Water Chillers. A Trane Air Conditioning Clinic, 1–70.

[5] Lane, R. W. (1993). Control of Scale and Corrosion in Building Water Systems (1st Ed). McGraw-Hill.